All through a factory test for HVAC tools In particular, the testing is often finished under stringent conditions inside a chamber that is equipped with instrumentation to permit distant monitoring and reporting of data.

Enable’s now think about the form of inspection you as being the producer or accepting client can order as the final check in the production system – that very last pre-shipment inspection on the product right before it leaves the factory for delivery to the customer. This test is called the Factory Acceptance Test or Unwanted fat.

Nonetheless, if the unit is Lively, you have to consider the wiring diagram and obtain The simplest way to simulate the signal coming from that Energetic machine. In most cases, you can also make use of a simulator. A simulator is a device such as this that can precisely reproduce a sensor output.

Scope. This is when the vendor guarantees the products satisfies the wanted style requirements. They Check out if all the things is in keeping with the drawings.

Now you may talk to, what If I don’t have an HMI put in with my panel? How can I see the adjust from the output? Effectively, that is also really easy.

The maker and shopper can select whomever they want from their providers to get present over the Factory Acceptance Test. It’s a good idea to have any/all of the following on area:

Method of testing & any tables and information to get completed in the course of testing studies from devices

Conducting the FAT around the producer’s web site provides several pros. Now we have use of all necessary tools, applications and staff to conduct complete testing and can offer instant resolution to any troubles uncovered. Getting access to the proper equipment more info makes sure that all components of the solution’s efficiency might be evaluated comprehensively, from functionality and dependability to protection and durability.

You can find a lot of pros to owning an Body fat, for the two events concerned. The seller can make certain that the process is operational and it helps the undertaking remain on target being sent in time.

To test the output, all you need to do should be to activate the inputs making use of simulated signals and find out In the event the contactor on the click here output might be energized.

An analog output sign can be possibly voltage or existing. We could measure this making use of an easy electronic multimeter too.

You may’t afford to pass up a single detail connected with protection choices. Here are a few factors to contemplate over the factory acceptance testing procedures:

Brands can customise testing established-ups and configurations as needed to simulate real-earth running conditions and assess the product’s overall performance under various situations. With their skilled staff on website, we will identify and diagnose difficulties a lot more properly in the course of the testing system and obtain worthwhile insights and recommendations for optimising the solution’s performance and addressing any deficiencies uncovered during testing.

Doing so causes it to be less complicated for all parties by removing next-guessing. Specify just how long the machine need to be dry-cycled; 24 hours least is recommended. Specify the amount of packages must be manufactured and at what speed. Specify disposal strategies for concluded packages. Though you’ll purchase the Fats, most gear suppliers will comply with a provision that Should the machine fails, any subsequent test is free of charge. Obtaining an in depth test approach should help ensure that you don’t quick-change the FAT. Doing a brief, shallow Body fat will inevitably display up as a dilemma from the 3rd change, nine months down the road.

Jonathan Taylor Thomas Then & Now!

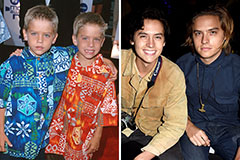

Jonathan Taylor Thomas Then & Now! Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Michael J. Fox Then & Now!

Michael J. Fox Then & Now! Burke Ramsey Then & Now!

Burke Ramsey Then & Now! Pauley Perrette Then & Now!

Pauley Perrette Then & Now!